COVID-19 Contact Tracing and Worker Density Mapping

The following resources share details on recently announced capabilities that may help industrial organizations navigate challenges being faced in their pandemic response.

MākuSafe launches contact tracing application in employee safety portal

MAY 22, 2020, BY KATE HAYDEN, Business Record COVID-19 Coverage

At the start of March, MākuSafe of West Des Moines was prepared to see four years of work launch its wearable employee safety devices into a global market. Around 8,000 of the two-piece armbands were earmarked to initial U.S. manufacturing clients, who would use the armbands to collect environmental data surrounding industrial employees — using indicators such as location and speed to identify workplace risk factors on a busy warehouse or factory floor.

Then the week that MākuSafe received their first large-scale shipment of armbands, the entire nation shut down to cripple the COVID-19 pandemic, CEO Gabriel Glynn said.

“…we have somebody that tested positive, now we’ve got to try to figure out who they’ve been around,” Glynn said. “We already have location — we have the location of all of the [employees], so we could see what people were around other people.” — Gabe Glynn

“Our customers [were] saying, ‘We’re not going to let vendors in, we’re not letting any outside visitors in,’” Gabe said. “We’ve been moving so fast for four years, and building things so fast … it was our first pause to go, ‘Let’s do some self-evaluation of the technology.’”

MākuSafe’s customers were seeking new protocols to help reopen workplaces to industrial employees, without risking the spread of a COVID-19 infection. Suddenly, the location data that MākuSafe armbands collect became a lot more interesting.

“Companies started talking about, ‘Shoot, we have somebody that tested positive, now we’ve got to try to figure out who they’ve been around,’” Glynn said. “We already have location — we have the location of all of the [employees], so we could see what people were around other people. Therefore, we could do contact tracing.

“All of this was already hiding in our data. We were just taking what was already there and applying it in a totally different way,” he added.

How Does MākuSafe Wearable Technology Work?

When employees using MākuSafe armbands arrive at work, each employee is assigned an armband that connects to a unique identifier in MākuSafe’s employer portal, MākuSmart. No personal identifying information is stored on the MākuSafe server, but that identifier tracks the employee’s location data on the worksite each day, creating a map of where the employee goes on-site and who else they come into contact with, said Chief Technology Officer Mark Frederick.

Now, safety managers using MākuSmart who learn an individual employee may have been exposed to a contagious disease can use the portal to identify who the worker has spent time with in a determined time frame — whether that’s two days or the last week, Frederick said. The web application will also report who in the contact list that worker has spent the most to the least time with.

“Immediately, you can tell that a given worker has spent the most time with one to three people. … That empowers the safety manager to go work with those three workers and ask some questions, further screening,” Frederick said.

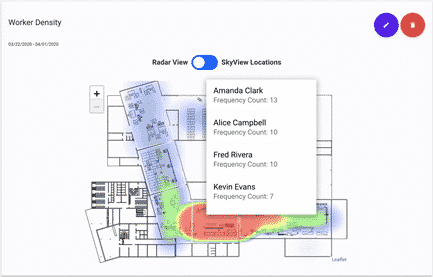

The company will soon be releasing a feature offering employers worker density maps — resembling heat maps — allowing managers to see where on the worksite they have the highest concentration of individuals and may need more social distancing protocols.

Help Manage COVID Spread + Safety Incidents and Claims with MākuSafe Wearable Technology

What’s Next for MākuSafe?

MākuSafe is seeking to hire a data scientist to help the company identify other applications in employee safety, and the company is getting back to installing armband kiosks for customers planning to use the armbands and employer portals to safely restart their work facilities.

“We had the data. We were sitting on it. We just hadn’t applied it in that way before, and so we’re very fortunate because that’s usually the more difficult problem to overcome,” Frederick said. “To fulfill these requirements of worker density and contract tracing by location didn’t require a hardware change, so we were very fortunate for that.”

Additional Resources:

Schedule a Demo:

Additional Resources for Download

The MākuSafe® Model:

Leveraging predictive information and just-in-time solutions to keep workers safe

Learn more about how MākuSafe® is using workforce wearables to track, predict and prevent near-misses to keep workers safer.